-

Posts

1,835 -

Joined

-

Last visited

-

Days Won

188

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

Dodge Journey runs perfect with ABS light on! Why?

John/Horace replied to NetherMined's topic in Engine & Transmission

Wow that’s weird. Almost going into limp mode but not really. What is year and milage of car. The only common 2.4 engine issue with idle and power problems is the electronic throttle body. Normally a lightning bolt symbol is one of the symptoms and usually codes. Plastic gears inside get worn and start to stick. Hitachi makes the oem replacement. How about cleaning up the grounds on both strut towers. Instead of a low voltage issue, could be a bad ground. This is a problem even dealerships would struggle with. Schematics and an ecm pin out diagram needed for trouble shooting, Mitchell on line login. Some people have had abs controller issues. They are on back order from dealers I think. Not a cheap part to throw at a problem like a map sensor. There was a recall for plug problem from water leaks. -

You have really covered all the usual issues, it seems. No codes is the most odd thing. As you know, drive by wire cars controlled by very low voltage signals from throttle and pedal sensor to ecm. May have to wait for it to get a bit worse and trigger a code. Something is running right on the edge. Reseat the plugs again to throttle body, pedal, map, etc. I hate parts throwing at cars, but on cheap wear items like CPS or map sensor I sometimes do.

-

Nice, Good scanners used. Were the old compressed intake manifolds seals reused when plugs were changed. Its better to change them , small air leaks can create cylinder misfire, maybe idle issue. Vac leaks can be tricky to find even with puffer. Does turning on a/c increase engine idle speed, curious.

-

https://jalopnik.com/car-thieves-hack-can-bus-headlight-wire-bluetooth-1850307214

-

No codes on your scanner. Dealer or better high end scanner might see codes. Some scanners only show basic obd codes. Must be sensor that turns on vac pump I guess.

-

Codes scan first, MAP sensor maybe. https://www.rockauto.com/en/catalog/dodge,2013,journey,3.6l+v6,1505070,exhaust+&+emission,manifold+pressure+(map)+sensor,11207

-

Found a decent link talking about stripped head bolt repairs. Helicoil is mentioned as not as good as time sert thread repair on aluminum blocks. But you need to have enough extra space for that style of repair. https://www.e46fanatics.com/threads/torquing-head-bolts.1287951/

- 4 replies

-

- stripped headbolt

- cylinder head replacement

- (and 2 more)

-

I’m pretty sure the bolts are torque to yield, so not reusable, here is a pasted clip from parts site. Torque-to-yield bolts are designed so that they can be elongated beyond their elastic limit into the plastic region without problems. When a specific tightening torque has been reached, the bolts are turned further through a defined angle, which pre-loads them into the plastic region. Consequently, no retorquing is necessary. Although it is a very effective means to get the maximum, uniform clamping load from each bolt, it permanently distorts the bolts, preventing them from being reusable under any circumstance. Check with machine shops, but I don’t think he’ll-coils are good enough for cylinder head bolts. Too many heat cycles and the huge amount of labor rebuilding motor makes it not worth the risk. Get a reman long block or short block or better yet a complete good wrecker engine. They are a common engine used in a lot of vehicles. LKQ or other reputable company. Free advice worth everything you pay for it. Cheers.

- 4 replies

-

- stripped headbolt

- cylinder head replacement

- (and 2 more)

-

Remote battery is the 3volt lithium battery, one in each remote. Can test with a multi meter, 5 yrs is longer than they usually last IMO. New they are 3.3 volts, some cars they will work at even less than 3 volts. The tire sensors also have lithium battery, that can’t be replaced, only whole sensor. Battery voltage often drops with temperatures, could have been triggered this winter. Can bus is very sensitive and phantom codes can turn up, could just clear them and see if they return. During start up on a cold day main 12 volt battery voltage also drops a lot when cranking, could have also caused codes.

-

2010 journey sxt crossmember specs?

John/Horace replied to moe mclay's topic in Brake, Chassis & Suspension

Welcome to the site. Looks like 100 foot pounds. If you use the very awkward search program it will come up with this chart. Front suspension: DESCRIPTION N·m Ft. Lbs. In. Lbs. COMMENT Brake Shield 10 7 89 Crossmember Mounting Bolts 135 100 — Crossmember Reinforcement Bracket Mounting Screws 50 37 — Hub And Bearing Mounting Bolts 48 35 — Hub Nut 160 118 — Lower Ball Joint Stud Nut 95 70 — Lower Control Arm Front Pivot Bolt 175 129 — Lower Control Arm Rear Pivot Bolt Nut 145 107 — Stabilizer Bar Cushion Retainer Screws 60 44 — Stabilizer Bar Link Nuts 48 35 — Strut Clevis-to-Knuckle Nuts 140 103 — Strut Rod Nut 60 44 — Strut-to-Tower Nuts 55 41 — Tie Rod Adjuster Jam Nut 75 55 — Tie Rod End Knuckle Nut 85 63 — Wheel Mounting (Lug) Nuts 135 100 -

TC light can come on from abs sensor issue. Code would show which wheel is an issue. If ETC light means the lightning bolt symbol , that points to electric stepper motor on the throttle assembly. Should be stored code as well. Try calibration procedure first. Super gasoline is for trouble shooting as well.

- 7 replies

-

- rough start

- etc

-

(and 1 more)

Tagged with:

-

It’s going into limp mode it seems. Could just be a coincidence it’s happening after car was worked on. It’s not easy to do something to a car to create intermittent failure days later…randomly. Not exactly a new car either. Codes are usually stored when limp mode triggered. Sometimes multiple codes that make it hard to pinpoint the problem. Throwing parts gets expensive fast, honest mechanics don’t like to do that. Could be anything from bad gas to a CPS, crank position sensor that is a fairly cheap wear item ($30 ish) or possible electronic throttle body starting to act up. Plastic gears on stepper motor can start to bind up.There is a recalibrate sequence for throttle assembly. Search the site for it, diy procedure. Being in the North, adding some gas line antifreeze to your fuel is also worth trying. Cheap to do, older stations can sometimes have an issue. Or just run a tank of high test through the car, lots of addditives in expensive high test fuel.

- 7 replies

-

- rough start

- etc

-

(and 1 more)

Tagged with:

-

Power Steering Fluid Leak

John/Horace replied to DodgeaWrench's topic in Brake, Chassis & Suspension

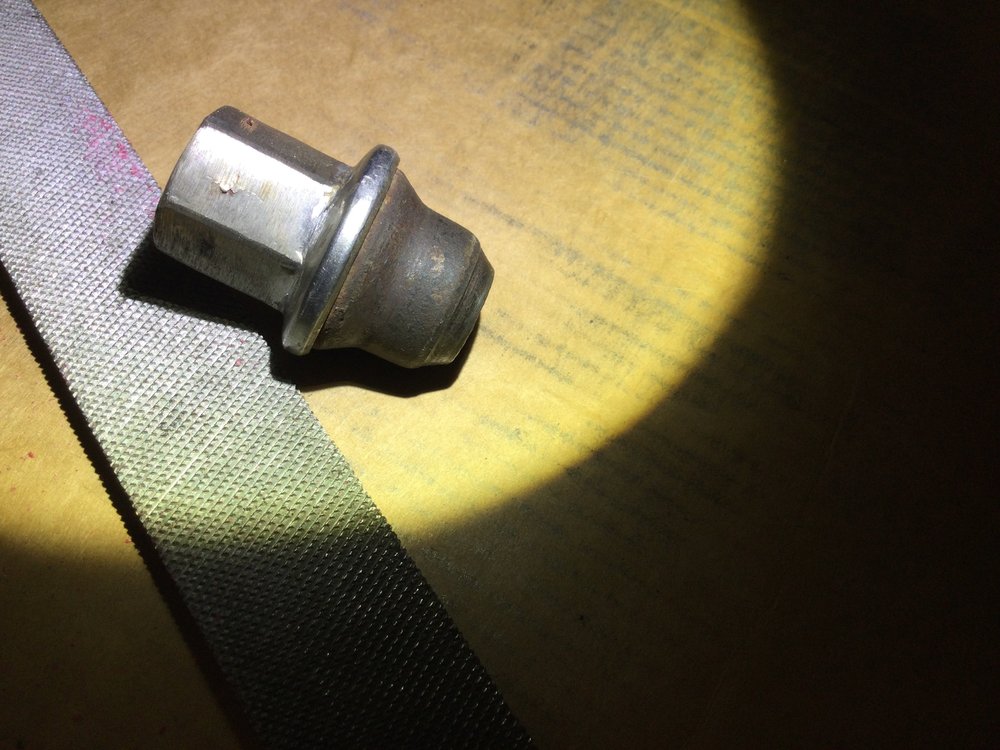

Looks good, glad you got your daily driver back on the road so quick. Factory unit had permanent crimp clamp on hose connections. New unit looks like it came with 4 gear clamps in pic. I like to double clamp connections if possible, but return line pressure is not that high normally. Harbour Freight/Princess Auto north of border have special stripped lug nut sockets. They are left hand threaded to lock on, seem to work pretty decent. Or hammer on crappy socket you don’t care about. Cutting torch sounds like way too much work, have never had to go that way, aluminum rims are fragile. -

Power Steering Fluid Leak

John/Horace replied to DodgeaWrench's topic in Brake, Chassis & Suspension

Tire shop will hammer on smaller socket to remove damaged nut probably. They can be filed back to flat surfaces to get them off and for temp use. But have to be changed soon. Lots of car companies use these crap sleeved nuts that become unusable with time. Salt belt areas especially. -

Welcome to the forum. It’s not Freon, it’s 134a refrigerant. If there is no pressure in system might be lots of moisture in system. A big contaminant that kills efficiency and system life span. Can pressure usually creates enough pressure for system to start back up. Adding can of air drier after r134a would help remove some of the moisture. If can doesn’t start it drawing, and jumping out low pressure switch harness doesn’t activate compressor, jumping out compressor relay contacts (moveable contacts shown on relay diagram) I think bypasses all control safety’s. Lots of pressure in these systems when their running ; wear your jock and your safety glasses.?. Free advice worth everything you pay for it.

-

Power Steering Fluid Leak

John/Horace replied to DodgeaWrench's topic in Brake, Chassis & Suspension

Winter weather can be crappy for outdoor repairs. The chrome sleeve can be popped off and a different size socket can be used on the smaller size steel nut underneath. Or you can file the sleeve so a socket can be put over sleeved nut. Switch to solid chrome nuts like McGuard etc. Factory lug nuts are crap, rust makes them swell up, softness makes them deform and not fit socket anymore. Over torquing torquing adds to problem as well. Return line is not crazy pressure, could do double clamped higher pressure hose repair on rusted section until weather clears. -

Power Steering Fluid Leak

John/Horace replied to DodgeaWrench's topic in Brake, Chassis & Suspension

Probably return line is bad as well, was recall ever done.? Looks like grill has to come off to get to cooler. Don’t run it dry, buy a quart of fluid asap. ATF4 is ok to use as well. https://www.google.ca/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwielPeEytH9AhWCFTQIHay2AmYQFnoECCoQAQ&url=https%3A%2F%2Fstatic.nhtsa.gov%2Fodi%2Frcl%2F2016%2FRCRIT-16V273-8350.pdf&usg=AOvVaw2m1VX_HnarQLUlyYSqpOfC https://www.google.ca/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwielPeEytH9AhWCFTQIHay2AmYQFnoECCsQAQ&url=https%3A%2F%2Fwww.ncconsumer.org%2Fnews-articles%2Floss-of-power-steering-assist-leads-to-dodge-journey-recall.html&usg=AOvVaw0fJ5Srw_JdctQ_QBu9cN8o -

It’s possibly a map sensor issue, but there should be codes showing up. They can be a wear item eventually. Good news is your compression is good, not an easy or cheap thing to fix. Cylinder Leak down test should have been checked too. Extra air coming in to intake can create random misfire problem.. I would replace intake manifold gasket first, not the expensive PCM. The main computer on cars rarely fail. Intake is a more logical cheaper guess. I can’t argue with oem parts for critical items, it is always the better choice. But money is tight every where now.

-

I haven’t had one of those in my hand before; work on cars as a hobby quite a bit, retired millwright. Looks like cast metal item, so fragile. I worry there are other cracks you can’t see. Awkward to get at later if it fails. Will probably come off in several pieces by hand fairly easily. Preheat with hair dryer if tight to install new one. Works together with your egr valve I think to keep oil inside engine. Probably mesh inside which could get plugged over time. Online sites for Mopar are decent and you guys have much cheaper shipping than we have up North. Unless money super tight, I would change it. If over 100k miles consider changing egr as well; they start leaking around that milage, I just changed mine for that reason. https://www.megacitymopar.com/cart.aspx

-

2012 Rear differential amount and type

John/Horace replied to giannid's topic in All Wheel Drive (AWD)

Look closely at magnetic drain plug. Should only have fine fur on it, no larger particle size metal shavings. Just less than a quart, around 0.8 lire I believe. Use good quality gear oil, factory fluid is semi synthetic. Look closely at the three lip seals, one on each half shaft and the other on output shaft; shouldn’t be any active drips. So dump and fill and inspection of seals. -

Depends on year. https://wranglerjkforum.net/threads/hoat-vs-oat-coolant-know-your-coolant-and-save-your-engine.26656/

-

Our 2014 has 231k kms and are still not bad. In first two years 2009-2010 the Journey suspension was really fragile and brakes were under sized. Lots of links talking about it. It was fixed after that and seems to be a little better than average. Although the newer suspension design can develop a constant rattle from bushings that wear out, rear latteral links also wear early if you haul loads a lot. Canada likes to sell Monroe after market struts; that are usually crap. Buy oem or KYB if possible.

-

Doesn’t look like they are doing you any favours , would be sending it some where else. Any decent mechanic can do this repair. Dorman, a fairly big US aftermarket automotive parts company makes an aluminum version. Some people on this site have had them installed with good results. If an original oem part fails prematurely, I will only use another one if part design has changed, or if I’m getting it at a significant discount. But that’s just me.