-

Posts

1,835 -

Joined

-

Last visited

-

Days Won

188

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

2011 Intermittent Electrical Issue

John/Horace replied to tsteves5's topic in Electrical, Battery & Charging

Decoupler can be changed by itself, awkward with alt in place. Our alt failed at 100k miles; very strong burning smell, decoupler was still working fine. The alternator It is a Denso factory unit; a very good brand name. I think 2015 they added a plastic top guard to prevent oil from valve cover leaking into alternator. The dealer Mopar rebuild I used was good price, had a 2 year warranty and contained 2 new studs and the now standard plastic cover for top of alternator. -

Brake Switch Circuit A Low

John/Horace replied to ntfd1023's topic in Electrical, Battery & Charging

Oops. -

2009 dodge journey 3.5 Awd transfer case leaking

John/Horace replied to qwizzy's topic in All Wheel Drive (AWD)

It’s obviously leaking from the seal, no video needed. The rubber can get old and brittle, metal shavings and dirt can get into seal and wear it out Don’t drive it until oil level is known, might get away with a seal if lucky. If it’s fixed right away. But if it’s already noisy the bearing/gear internals ran without oil and whole ptu wil need rebuild or replacement. Most gear boxes have a accessible fill plug and can have level checked, and can be topped up if low. This unit can’t be. -

2011 Intermittent Electrical Issue

John/Horace replied to tsteves5's topic in Electrical, Battery & Charging

Weird issue. The small wire going to alternator is linked to pcm/ecm so it could trigger battery light coming on. But measuring 14.3 when light is on I think means light should not be on at all. What is the gauge cluster showing for voltage when light is on. Bad drive pulley coupler could also trigger battery light, but again voltage would be low. When my wife’s alt failed it was intermittently at 10-11 volts charging, then completely failed. Voltage on small wire at alt when the light is on would be useful. It has to be a good strong full battery voltage signal. -

2009 dodge journey 3.5 Awd transfer case leaking

John/Horace replied to qwizzy's topic in All Wheel Drive (AWD)

Looks like output shaft lip seal is leaking. First thing is to figure out if you have enough oil in ptu unit to keep driving temporarily until it’s fixed. People have posted on site how to dump and fill the 75w90 through vent hose line, slow and tedious, but better than trying to use the factory refill plug that is crazy to get at on the 3.6 engine, 3.5 might be different. Oil capacity is just less than a quart on 3.6 unit about 800 milli litres full. No dipstick so dump and fill is only way to determine current level. It’s possible drive shaft can be removed and new seal can be installed with unit in place if leak is caught early and unit doesn’t have major damage. Usually it’s cheaper to get a auto recycler used ptu then to rebuild or buy new ptu (power take off unit). Look for metal shavings on the magnet drain plug and in the oil that is dumped out. If only a few drips over night, a refill might give you time to check around for quotes. https://www.rockauto.com/en/catalog/dodge,2009,journey,3.5l+v6,1442283,drivetrain,transfer+case+output+shaft+seal,8440 -

I’m vey impressed with your timing chain/cylinder head work. Not a easy job on these cars. Is it running smooth ? I don’t think valve cover would be large vacuum leak category, would be oil leaks as well. I’m hoping map sensor or O2 maybe. Will take some trouble shooting. Off the google. Causes for this code may include: Engine vacuum leak (large) Defective oxygen sensor/s Burnt, chafed, broken, or disconnected wiring and/or connectors Engine exhaust leaks A faulty mass air flow or manifold air pressure sensor Bad fuel pump or clogged fuel filter Read more at: https://www.obd-codes.com/p219b Copyright OBD-Codes.com If the engine is running smoothly and the code P219B continues to be reset, start the engine and allow it to reach normal operating temperature. Allow the engine to idle (with the transmission in neutral or park). With the scanner connected to the vehicle diagnostic port, observe oxygen sensor input data on the data stream. Narrow the scope of the data stream to include only pertinent data and you will get a faster response. If the oxygen sensors are functioning normally, voltage on pre-cat oxygen sensors will cycle continuously between 1 and 900-millivolts once the PCM enters closed loop operation. Post-cat sensors will cycle between 1 and 900-millivolts as well but they will settle at a certain point and remain relatively stable) compared to the pre-cat sensors). Oxygen sensors which fail to cycle adequately should be considered defective if the engine is in good working order. In most cases, you will rectify this code by correcting a rich or lean running engine

-

The spoked rims have a nice look. Not sure how they would do with curb or mega pothole incident. Clearly not a strong as more closed in style alum rims. Tires for the 19 are also a little pricy.

-

Kinda interesting, very good back yard repairs. People talk about their Journey rusting, this is an example of real rusting in a rust belt area. https://www.theautopian.com/how-a-michigan-man-uses-a-cheap-welder-to-keep-his-toyota-4runner-family-vehicle-on-the-road-after-its-frame-began-rusting-to-the-ground/

-

Just swapped snows off wife’s Journey today. Also jinxed myself. Snow tires save the rims from salt. Salt use is being cut back by roads crews up here, more sand being used. Makes snows help with ice on interstate type roads. Studs banned where I am living now, too much road wear. Ran lots of studs on snowmobiles I had.

-

Timing question on 2015 Dodge Journey sxt 3.6l

John/Horace replied to Raiderfan717171's topic in Engine & Transmission

I haven’t done a chain on a Journey. But have replaced chains and belts on a few other vehicles. Has the engine moved off top dead center.? If it hasn’t and all the paint marked sprockets and the chain still line up, I would say you are fine. There is some internal play or back lash built in. On timing belts after install and tensioner has been released; I always do 720 degrees or two turns in the clock wise direction and line up the timing marks again. You might find them even closer after this procedure. Good confirmation to very labor intensive procedure. -

Interesting, especially the comments section. Sometimes having the latest and greatest creates it’s own problems. https://www.theautopian.com/how-an-involuntary-over-the-air-update-left-a-bunch-of-volvo-owners-stranded/

-

Service AWD, ABS, TC maybe transaxle?

John/Horace replied to KrossBones's topic in All Wheel Drive (AWD)

Checking the rear diff and front ptu oil levels are a good idea. Signs of leaks, dark stains just below driveshaft or c/v shaft locations makes it even more important. Front ptu has no dipstick to check level. Dump and fill will tell you amount of 75w90 that was there. Full is only around 700-800 milli litres. Rear diff has side plug for level gauge, holds around 1.3 litre I believe. Look for signs of metal in any oil dumped from transfer cases. Grinding noise could be related to brake work done, you need to investigate more. -

Welcome to the site orthotec28 , not trying to be harsh. No capital letters being used in discussion. ? I think it’s either Borg Warner or Getrag designed system; decent oem suppliers for years. Sometimes there are weak links for reliability on a vehicle that deserve updating. But even F150:trucks are using one piece unserviceable driveshafts units on some models. It’s the direction automotive has been moving for a while; throwaway not rebuildable. If you were going to go off road a bit and wanted a switchable a system that stayed in awd for a period of time. It would necessitate large changes to the factory system. A custom 4x4 builder could for a ton of money probably do something. But the driveshaft shaft and transfer cases are really tucked in underneath, a major lift and would also be needed. Switching vehicles a better option imo.

-

Why. It’s a simple maint free part time system. You cant add any performance modifying it. It’s a balanced high speed turning driveshaft assembly with sealed connections and a single hangar bearing. My wife’s is still functioning at 225k kilometres or 140k miles and hasn’t been touched. Very pricy to replace if it does go, oem is around $600 I believe. My Jeep’s with double cardigan and ujoints, multiple grease fittings needed way more maint, but they were designed for continuous use and had a lot more torque on them. The Journey system is simple and fairly reliable if you keep a close eye on the oil level in the ptu and rear diff systems. Run them out of oil from a lip seal leak and you have a very expensive repair.

-

If you search in the site, you will find not really. How many miles on engine ? You can remove surpentine belt and run car for 10 seconds, careful, no water pump flow like this. This takes, everything external that spins out of the mix. If still a noise it is internal like timing belt tensioner or roller follower, valve lifter etc. Water pump bearings can knock when they start to fail; but usually lip seal on front starts to leak, or weap hole shows signs. A high milage kinda fIx usually. Engine stethoscope can pick that up the noise. If you are going to a shop and you have to explain how to trouble shoot….you are at the wrong place.

-

Interior Dome Lights

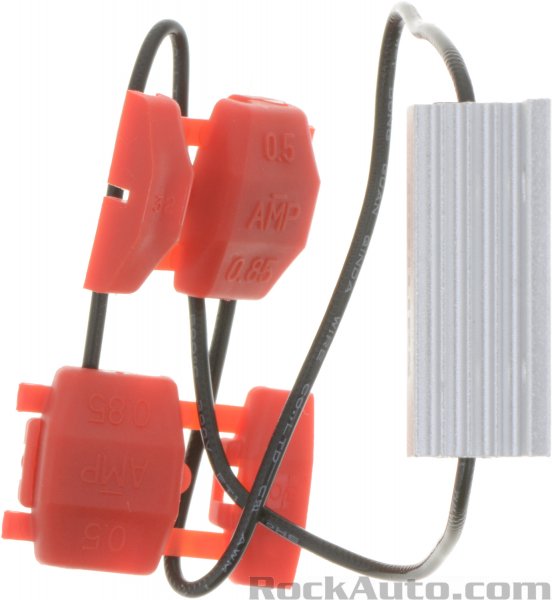

John/Horace replied to CleanJourney2017's topic in Electrical, Battery & Charging

Led load resisters needed on the circuit, or as OP’s are saying, buy better bulbs. https://www.rockauto.com/en/tools/electrical-bulb+&+socket,tool,led+bulb+load+equalizer,49474 -

You need to disable traction control when you get stuck. It allows a bit of wheel spin for getting out. You can’t spin the wheels for long periods of time without overheating transmission very quickly. Try unhooking battery for a few minutes to see remote possibility it’s just stuck in limp mode. A code reader that can access transmission codes is needed to see what parts could be damaged. Torque converter, pump, fluid body etc. It may not be the first time the car has been in the rhubarb; automatic transmissions can be fragile.

-

If vehicle originally had a functioning dealer camera already already, the code would have been installed. You are correct the part number is wrong, here is a Canadian oem part link. https://parts.motorcitychrysler.ca/p/Park-Assist-Camera-Rear/74170856/56054158AG.html I think real issue could be firmware in the new oem camera reacting to the Apple car play aftermarket interface unit you added. Electronics sometimes don’t play nice when copy write stuff is involved. Not much plug and play in the proprietary automotive world. I would try a generic aftermarket cam mounted in place of the factory cam. Try for higher IP68 I think water rating and best pixel rating you can find. Alpine aftermarket cams someone said are not bad, around $95 ish.

-

Lots of car parts are hard to get right now with all the supply chain disruptions. As I’m sure you know the head bolts are stretch bolts or t-t-y torque to yield design; Rockauto has them for as little as $30 for Mahle a good brand. Some times it’s the little details that can get you. With the low milage a head swap should be the better option over a wrecker motor IMO.

-

Looking for new headlight assembly

John/Horace replied to Drewbear's topic in Glass, Lighting, Mirrors, Sun Roofs & Wipers

Link is not working for specs. Canbus electrical systems can act up with added LED lights, create hyper flashing etc. You need a well designed system to avoid issues. I would buy a tube of clear silicone, remove both lights, dry with a hair dryer, then apply silicone where clear lens joins black housing. At 2019 car might be new enough to try for warranty coverage, the headlights are not cheap to buy. -

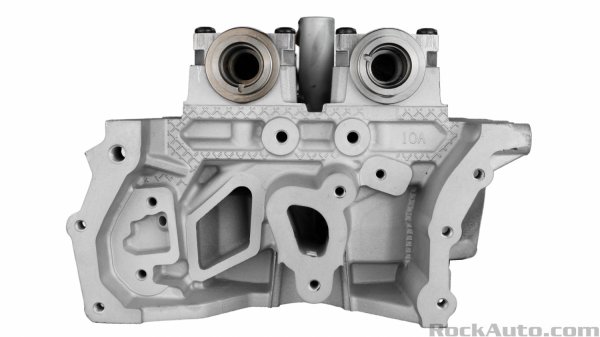

I have never removed a Journey cylinder head. Man that’s a big job. Here is a few pics of a left reman head, hope it helps maybe. You need it for recore I assume, needs to be in good shape. Tapping with a brass mallet on a beefy spot might separate gasket from head. Stuff can get welded together by the heat. Use a good torque wrench on the reassembly.

-

Welcome to forum. Try TIPM (computer) reset by disconnecting the DJs battery at the negative jumpstart connection for 10-20 minutes.

- 2 replies

-

- rear

- turn signal

-

(and 3 more)

Tagged with: