-

Posts

1,832 -

Joined

-

Last visited

-

Days Won

187

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

Welcome to forum, great first post.

-

Dealer uses your vin for parts look up. Since your car wasn't built with the handles, it won't show up in a search. They will have to do a manual search, making odds of getting wrong parts a lot higher. Ushally lots of whinnying as well.

-

Try the upull section of an auto recycler. You can see how it comes out, measure location of sheet metal bracket where the inserts go into. Pull inserts and hardware from the wrecker car. Good pic on this link of the cut out locations etc. I don't think the side curtain airbags are an issue. https://www.rockauto.com/en/catalog/dodge,2014,journey,3.6l+v6,3300354,interior,headliner,14287

-

abs light 2015 dodge crossover grinding noise

John/Horace replied to Glenf88's topic in Brake, Chassis & Suspension

These guys hpseem to have the most accurate parts lists and they sell OEM as well. I don't work for them. Have caught other parts stores checking their site as a cross reference. ? https://www.rockauto.com/en/catalog/dodge,2015,journey,3.6l+v6,3309784,brake+&+wheel+hub,abs+wheel+speed+sensor,1912 -

Comes out with first a 90 degree index twist motion, then a slight pull. I don't incourage throwing parts at cars, but this can be a wear item on 3.6. Plugs are are due as well.

-

Yeah no maf only MAP sensor, easy 5 minute change. Free advice worth everything you pay for it. ? https://www.rockauto.com/en/catalog/dodge,2012,journey,3.6l+v6,3015568,exhaust+&+emission,manifold+pressure+(map)+sensor,11207

-

I think I only paid dealer $30 for the correct filter. It's an important filter. Approx 5 quarts with a filter change pan drop. Can use a suction pump through dipstick with a hose and get about 4 quarts out. Filter change better.

-

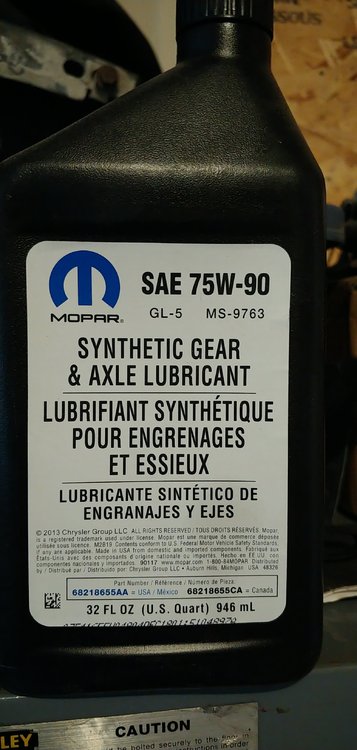

My manual says 75W90 some where. The dealer only sells synthetic 75W90. Any good brand oil is fine, syn is better. I have used both dealer and Lucus brand syn. Rear is 900 ml approx and rdu is around 800, so almost a quart in each. Could buy a jug and use it for two changes, large jugs much cheaper. I would do tranny ATF+4 now as well, it's a fairly cheap semi synthetic oil.

-

2012 Dodge Journey misfire cylinder 6

John/Horace replied to Belcherd19's topic in Engine & Transmission

You said carb cleaner, I hope you meant fuel injection compatible cleaner. Carb cleaner kinda harsh, injection seals don't like it. If it fouls again, some shops have a injection cleaning set up called Motovac or something similar. They unhook engine fuel line and run car on a concentrated cleaner for 10 mins. Works well. The vvt have sensors with screens in them. You might get cam codes from the carbon sludge. The cat could be a mess too. -

Welcome to the forum. Cool diy. You could add a few small strips of metal or aluminum with rivets to reinforce the corner of support where slots are. In case there is flexing. I've had some close calls with deer, just lucky I haven't made contact yet. Good thing airbags didn't trigger with the deer hit.

-

2010 RT AWD front gearbox failure

John/Horace replied to Raythecaddie's topic in Engine & Transmission

I don’t think it’s the transfer case. https://www.moparpartscanada.ca/oem-parts/mopar-transfer-case-rl071706aa?c=Zz10cmFuc2Zlci1jYXNlJnM9dHJhbnNmZXItY2FzZSZsPTEmbj1TZWFyY2ggUmVzdWx0cyZhPWRvZGdlJm89am91cm5leSZ5PTIwMTAmdD1yLXQmZT0zLTVsLXY2LWdhcw%3D%3D Front drive shafts come out of the transaxle part of transmission. Unfortunately I think you will need new tranny if the aluminum casing is cracked. . Could try reman or wrecker units with lower miles, LKQ useful. Could be just a blown c/v shaft which took out lip seal on side of tranny and caused leak. Maybe fixable and no new tranny if your lucky. Don’t drive it further, tow it. -

I had to try and help...In a hemi owner. 2015 Ram.

-

A little early for the plugs, you will get codes if they are malfunctioning. At a 100k miles I only had 10 thou of wear on electrodes. Was-doing oil cooler replacement so plugs changed too. Fluids more important, pricier repair if a break down. Upstream O2 does fuel trim rich/lean, it’s even early for that, but gas is expensive and that might improve fuel economy slightly, plugs wouldn’t. My 2 cents.

-

Codes first. MAP sensor maybe.

-

Thanks for the info, helpful for the site. Cars can do weird things and make trouble shooting tricky at the best of times. If you remove intake, new rear plugs might be a good idea if they are close to being due. Most of work done at that point. Random horn mmm. Is the airbag light showing on dash, is there a drivers side code for airbag. Horn often shares clockspring wire harness. Switch mechanism in steering possibly.

-

It’s possible, dealer electrical Tec would know for sure. I think ecm more likely, it even has the vin number programmed in. I do know it’s a combination of mileage and time and driving load characteristics. I’ve had the monitoring on more than one vehicle, the 2015 Ram pick up system seems not too bad compared to others. I think one of the defaults is 6 months maximum time between oil changes on some monitor systems, which I don’t really agree with when using full synthetic. Coil pad and all maint listed including oil changes, like someone mentioned, is what I do. I have read on other forums that the system is calibrated on the recommended factory oil. My older F150 specs were semi-synthetic so that is how they extended cycle a little longer. There is nothing wrong with just basic blended oil and shorter changes IMO. I only use expensive synthetic when it’s in sale. Costco has their own brand of syn that is always a good price, BITOG says it’s not bad. Being old school...and old, I can’t bring my self to going more than 6-7k miles on oil, even full syn.

-

Check the grub screws for tightness. I think they use blue loctite on them. If it’s cracked flex plate I think tranny has to be pulled to change it. Very unfortunate, but your head change work did stand up, which is good.

-

I agree with 5rebel9, not that likely the ecm. They rarely go on most vehicles. You need to clear that code with proper scanner and then watch live data with vehicle running. More trouble shooting before throwing parts at it.

-

Horn Shuts down engine ONLY

John/Horace replied to Deadboltdon's topic in Electrical, Battery & Charging

Scan for codes first. Unplug horn and confirm random stalling still occurs. If cps crank position sensor is original change it. CPS doesn’t always set a mil code. Report back if it fixed it so car forums are useful. -

There are a few body shop supply stores that do that here. But not in small towns. Usually they won’t do a single can, more like 2-3 cans. Investigate shipping cost from Quebec after google translation. I use to have my snowmobile piston jugs nickosil coated in Quebec, even with shipping, best deal north of border.

-

Best NGK Spark Plugs for for 2014 3.6 L FWD ???

John/Horace replied to Kev100's topic in Maintenance & D.Y.I.

Very close to there actually, few miles north of there. I did notice extra planes, wasn’t sure what is was. Toronto has a very big air show at the end of the summer, international air show usually. Lots of very unusual older military planes etc. I’ve only been is this area for the last year, but I have in the past crossed over into Buffalo for the outlet malls etc. A lot of beautiful old century homes and architecture in some areas. Looking forward to life and border returning to normal. Cross border shopping was always very big. On topic ...even for OEM a dealer stuff. -

Best NGK Spark Plugs for for 2014 3.6 L FWD ???

John/Horace replied to Kev100's topic in Maintenance & D.Y.I.

Yeah a lot of stuff is marked up higher. Partly because of extra shipping distance, currency exchange, lower volume of sales. Govmint cost mark up is the trickier one. Lots of people here pissed off with extended border closing. I’ve had both shots for a while now. Vaccine roll out was not that well handled here IMO. Just like everything else, there is a hidden political element to it now. I’m living right at border, business hit has been huge. Not sure how some of them will recover; even with the hand outs. Better days ahead. On topic, I don’t mind paying a bit more for better quality dealer stuff. Especially critical components. -

Best NGK Spark Plugs for for 2014 3.6 L FWD ???

John/Horace replied to Kev100's topic in Maintenance & D.Y.I.

Actually the Journey 3.6 plugs are one of the easier V6 plugs I’ve ever changed. Hyundai 3.8. 3.5, 3.3; Kia 2.7 , F150 4.6 3V are all much worse for more fasteners and electrical plugs to remove. Someone said they paid $11 for oem. I guess our free health care is’t so free after all. ? https://www.moparpartscanada.ca/oem-parts/mopar-spark-plug-sp149125ae -

Using 1st gen driver door on second gen

John/Horace replied to Ottawajourney's topic in Exterior & Body

Welcome to the forum, great first post. Sounds like we now have a body and frame expert on the forum. Cheers.?