-

Posts

1,830 -

Joined

-

Last visited

-

Days Won

186

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

I’ve used NTK who make a lot of oem O2 sensors on my 3.6 dodge, never had an issue for 12 months now. About one quarter of the price. Maybe not as good but car won’t go another 180k kms anyway. I have had issues and won’t use Bosch sensors or spark plugs. NGK owns NTK.

-

Haven’t worked in a 3.5 since my brother got rid of his 300 two years ago. It had mostly electrical issues so I hardly touched the engine. No pics makes it guessing game. Leak on front of engine often water pump; bearing weep hole is hard to check out without mirror and timing covers removed. But weep hole is a pressurized leak normally. Milage kinda low for a pump change. Maybe micro crack in one of the plastic parts. Is this pic the big/small hose part you changed ?

-

hard then soft brake pedal

John/Horace replied to wpginterceptor's topic in Brake, Chassis & Suspension

Vacuum booster has check valve so it holds vacuum for a period of time...say a Wallymart shopping visit for 2 hrs so assist still there on restart. Over night especially in winter, vacuum lost and engine needs few seconds to recharge booster, so initial stiff pedal. If pedal pressure is varying while driving, could be a master cyclinder issue. Since about 1969 all master cyclinders are two stage design (probably US federal gov safety mandate). If primary seal fails, the pedal almost to the floor will still have a large amount of braking ability. Not full since back up stage is smaller bore, but enough to theoretically stop car. My first car a 1967 beetle had four drum brakes and a single stage master cyclinder; but a working hand brake got me home once. So it is important to pay close attention to how well your brakes operate. Minimum standard ahhh no. -

driver front brake dragging and overheating

John/Horace replied to scootaloo89's topic in Brake, Chassis & Suspension

-

driver front brake dragging and overheating

John/Horace replied to scootaloo89's topic in Brake, Chassis & Suspension

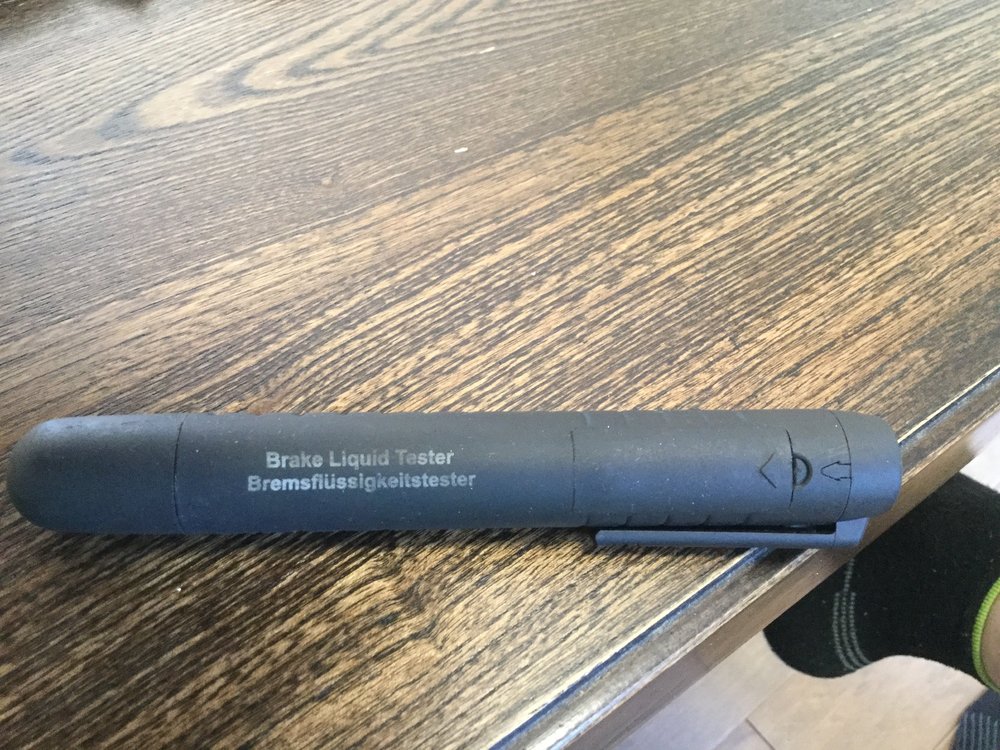

Sometimes new piston (which is available) is needed if it has any scoring visible on it. If fluid is over 5 yrs old or moisture percentage from tester is over 0.2 percent it’s a good time to replace it. -

driver front brake dragging and overheating

John/Horace replied to scootaloo89's topic in Brake, Chassis & Suspension

How were the slider pins? Need to be cleaned up and lubed with Sylglide or similar synthetic brake lube. Should float freely. New pads are often too tight and need some clearance added on the contact surfaces with a file or grinder. Although one side is working ok so..... At higher milage calipers can start to seize up. Either new seals from a rebuild kit or a reman caliper might be needed. -

hard then soft brake pedal

John/Horace replied to wpginterceptor's topic in Brake, Chassis & Suspension

Vacuum assist versus no vacuum assist. When car runs you have power brakes...which is vacuum assist via the booster shown in pic. Makes pedal easier to press. -

2014 Dodge Journey Limited starting problem

John/Horace replied to Josh Lambert's topic in Engine & Transmission

If you can get teenagers working, my hats off to you. Cut her some slack for the radio, we have all made that mistake at one time or another. Glad you like your journey. -

2014 Journey hesitates on acceleration

John/Horace replied to wicketbear's topic in Engine & Transmission

Even if no light on dash scan anyway. Any service work recently completed? -

2.4L Intake Runner Replacement

John/Horace replied to JimBellArmada's topic in Engine & Transmission

Often a obd diagnostic tool is used for some sensor replacements. Plug and play does not always work. At a minimum try clearing the codes again with a standard code reader, unhooking battery usually not helpful. Most mechanics have some type of advanced scanner Autotel etc for this kind of work beyond regular obd11 scanning. -

2.4L Intake Runner Replacement

John/Horace replied to JimBellArmada's topic in Engine & Transmission

There may be a relearn procedure for the new sensors you replaced. PCM reflashing. Are the same codes coming up after parts change? -

I’m far from an expert on compression testing , there are various ways to get same result. Exhaust manifold always stays on shouldn’t have impact on compression test. TDC doesn’t matter for compression, it’s only useful for setting up timing. If all cam timing marks, all four and crank pulley Mark is on you should be fine. Cyclinder 1 will also have piston full extended at TDC. I usually do 720 degrees or two revolutions CW and make sure marks are still lined up, then I put covers back on. I like to paint Mark belt and pulleys before removing and then transfer marks to the new belt before install. Lots of licensed mechanics do this as well. Some engines the marks are harder to see, paint marks eliminates that problem. A car will kinda run on three cyclinders so that doesn’t prove anything. Cyclinder one is on the rear bank, closest to front of engine where pulleys are. Problems seems linked to the pulley key issue.

-

Cast meaning cast aluminum ? I’ve never seen aluminum used on a key way, put a magnet on and check. Most compression test procedures say to remove all plugs (manifold on back of v6) for compression test. Disable fuel pump hold, fully charged battery, all coils would be unhooked so no spark source would be present. Approx same number of cranks for each cyclinder. If valves not functioning properly then valves can’t allow either air in or air to be held in place for pressure build up; at least that what it seems. Got a picture of this pulley key way part issue. Ive done several timing belts on overhead cam engines, very awkward to do, some people use a set of wedges designed to hold pulleys from moving. As long as you get it on with out wrecking belt and everything gets retorqued that was loosened, I don’t a problem.

-

I don’t see three broken rings or bad pistons since it was just running. Rings can get gummed up from carbon if car is burning significant ,oil. Fixing cam pulley looks to be the right thing.

-

A new key way can be cut with a broaching tool in a shop with arbour press. But if small piece comes out cleanly and slot is good then a new piece of key worth $2 can be used. Some filing for sliding fit. Key stock is mild steel, acts like a sheer pin if shock loaded. Or go full McGyver since you have another engine. Line it up and tac weld in place. My lawn old Craftsmen tractor has a lot of welded in place stuff, new tractor parts are gold where I live, same as shipping.

-

Key stock is not that hard to come by, if the pulley key slot is ok I would replace key. Or use paint marker on pulley and shaft and confirm it’s not slipping. How about a table spoon of oil down the three cyclinders and try for compression. Wet test in other words.

-

Need to get out multi meter and figure out polarity etc. What has 12 volt positive (probably red) and what is on ground side. Harness needs one or both of blue wires to complete circuit, without a diagram you need to study it. It’s possible the low side switch is defective and causing problem, so try testing contacts with plug removed. Jumper will obviously go on plug end of wire harness feed, but I’m not sure where without a diagram.

-

He is not talking about removing battery, he is talking about testing diodes in alternator by unhooking positive battery terminal.

-

That’s a 1980’s car test maybe, With all the electronics and computer stuff on new cars I would not want to try that. Not to mention arc flash over a battery, which if low can be producing hydrogen gas, explosive. I have seen the results of a battery blow up before.

-

Wont start after head gasket replacement

John/Horace replied to Borjawil's topic in Engine & Transmission

I try to compare new ones to old used ones if it’s not destroyed when removing. Sometimes when they don’t mark it, it doesn’t matter. Locally where I am there are several Oreilly’s type places run by kids, some half know what they are doing. Then there is the more expensive long time in business parts guy with staff with gray hair, one who is retired mechanic. Trade gets 30 percent discount, if I whine I might get 10 percent. They might tell you to go home and drag your cyclinder head or old bearing into store; but they will not knowingly sell your the wrong part. Like the dealer parts guy who warns you he hasn’t sold the part you are buying in 4 plus years; sometimes worth the extra hazzle to get to. Watch that surgery recovery. -

Rear blender door actuator Mopar $53 Canadian pesos, convert to US dollars on site. Press info link for decent jpg pics on Rockauto. https://www.rockauto.com/en/moreinfo.php?pk=9876484&cc=3015568&jsn=449&jsn=449 https://www.rockauto.com/en/catalog/dodge,2012,journey,3.6l+v6,3015568,heat+&+air+conditioning,heater+blend+door+actuator,10721

-

This looks like low side switch, it’s on the same line as charging port. High pressure side on a/c can reach over 210psi-ish which is shrapnel making velocity potential. Wear your jock and your goggles.?? If some refrigerant charge still partly there and no air (moisture mainly) got into system might be ok. If compressor starts up, start looking on high side, especially condenser coil across rad for hissing large leak.

-

If you can, remove the wheel spacers. They tend to wear out bearings and it’s better not to have them if possible. How many miles on car? Some mechanics have listening device to trouble shoot bearings etc. Rear driveshaft on awd vehicles can often be removed temporarily to prove if that’s the cause, pricy item to replace. I drove my grand Cherokee for its last two years without rear drive shaft, $1000 viscous coupling repair couldn’t be justified. Removing driveshaft was a 15 minute one wrench only job. There is one changeable part on driveshaft. https://www.rockauto.com/en/catalog/dodge,2014,journey,3.6l+v6,3300354,drivetrain,drive+shaft+flex+joint,10701

-

Which engine four or six. Scanning for codes is usually first step. Fuse for push button start in passenger kick panel should be checked F121 I believe. It’s called wireless control module in owners manual.

- 3 replies

-

- check engine

- wont start

- (and 4 more)

-

Yeah should be a signal triggering clutch on compressor from hvac system. I haven’t had to work on my wife’s journey a/c yet, more familiar with older hyundai a/c.