-

Posts

1,835 -

Joined

-

Last visited

-

Days Won

188

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

The deposition of black DLC coatings is a precarious process that can only be executed by a DLC coatings expert, such as Bekaert. DLC (short for Diamond-Like Carbon) coatings are the protective layer one can find on coated engine components. These have a typically black color, which makes the coated components easily recognizable.

-

2013 Journey 2.4L - No Crank, No Start

John/Horace replied to FourthGauge's topic in Electrical, Battery & Charging

Check LKQ they are big company. Price seems high for 200k. You mentioned the oil pan was replaced on engine. This means it probably stopped holding oil at some point. Engines don’t like to run on low or no oil for very long, tends to drastically shorten life span. Kids often crank the tunes and drive to it stops without paying attention to what car is doing. Need to train them early, if I ask my daughter who lives 2 hrs away how is her oil. I usually get a text with a picture of the oil level on the dipstick. -

Each cam pulley should go back on the cam it came off of. Could be slight tolerance difference between the pulleys. There could be a burr on one of surfaces, use scotch bright etc to polish up surfaces. Sometimes sliding pulley on first and then putting in key works better with some assembly’s. Got a picture of what has 1/4” movement. Cams are fixed in place from what I have seen.

-

Camshaft position sensor bank 1

John/Horace replied to shelllmarieee's topic in Engine & Transmission

Which engine, how many miles. Common Symptoms Error Code P0344 can be tricky, as sometimes, it may not be preceded by any symptoms at all, other than the Check Engine light. If there are symptoms, it usually would be: Engine cranking but doesn’t start Hard starting Engine dies and doesn’t restart Engine lacks or loses power Rattling sound (metallic noise) coming from the engine Possible Causes There are many reasons and factors for a vehicle to have this code. Some of the most common causes are: Intermittent open in the power supply circuit to the CMP sensor Intermittent short to ground in the power supply circuit to the CMP sensor Intermittent short to 5V from the signal circuit to CMP sensor Intermittent short to ground in the signal circuit to the CMP sensor Intermittent open in the signal circuit to the CMP sensor Intermittent open in the ground to the CMP sensor Damaged CMP tone ring CKP making intermittent signals occasionally Other possible causes can be: Dead or weak battery Faulty starter motor Poor electrical wiring connection to CMP sensor Short in starting system circuit How to Check When this code is saved on the vehicle, technicians conduct their troubleshooting by inspecting the CMP and CKP sensors and their respective wirings. They will check the wires and look for signs of damage, such as chaffing, rubbing, burnt areas, or melted plastics. Then, they will proceed to check the connectors and terminals. These troubleshooting steps can usually tell technicians the source of the problem. How to Fix Depending on the cause of the error code, there are multiple ways to fix it, which include: Cleaning the electrical connections to the CMP sensor Replacing the faulty CMP sensor Replacing the faulty CKP sensor Replacing chaffed, melted, or damaged wirings Replacing weak or dead battery Intermittent signal from the CMP may mean many different issues that can be potentially serious. If left unaddressed for extended periods of time, the vehicle will start stalling and may not start again, or fail to start after being shut down and left. -

Fuel stabilizer recommendation (due to COVID-19)

John/Horace replied to Flare's topic in Engine & Transmission

Super gas has more additives so a better shelf life I have always heard. Its also dirt cheap now. For small engines that get stored and hate ethanol it is recommended by repair shops. Stabilize can’t hurt but IMO not really needed, like moderator is saying, starting car so battery charged and engine parts get lubricated etc probably more useful. Drive around block to get rust off rotors and mechanical parts get cycled a bit, even better. -

Battery maintenance impossible

John/Horace replied to Rough Independent's topic in Electrical, Battery & Charging

Both journeys I look after have standard vented lead acid batteries. Same as the factory battery was. Battery is hard to get to and not as well shielded from moisture with fender liner plastic that they should be, I agree. I use battery terminal spray during install and it helps a lot with terminal corrosion from ion exchange through the air. Heat and vibration are biggest battery life killers. Fender liner noticeably cooler than engine compartment so some people have good luck with longevity it seems. Constant battery terminal cleaning shouldn’t really be necessary. But cleaner is better. If you are constantly getting corrosion coming back try the terminal spray protection. Sometimes this corrosion reforming rapidly is a sign of a weak alternator or battery, load test system to make sure you are getting 14.2-14.6 ish with lots of stuff turned on. -

Scan for codes, even if mil light is not turned on.

-

Cams turn two to one ratio to crank shaft. So TDC is crank pulley pointer on timing cover lined up and cyclinder 1 is fully extended. Usually pull out spark plug and check with screwdriver that piston is extended. Could check this on reassembly after belt is lined up.

-

Welcome to the forum. You probably know most of this already if you work on cars regularly. You said left head so the six engine. I think that was first year of 3.6 issue only, maybe someone will answer if they know for sure. How many miles on engine, still any power train warranty left. Could mark cyclinder 2 coil and swap location and see if it follows to another cyclinder. My bet is bad coil. Did you use new o rings on lower intake while doing spark plugs. Vacuum intake leak can cause cyclinder misfire occasionally. If you are in that deep, cyclinder compression test useful info to eliminate that possibility. Even a bad cam or crank sensor can create a cyclinder misfire I’ve heard, although never experienced. Injectors seem to rarely fail on cars, still a possibility.

-

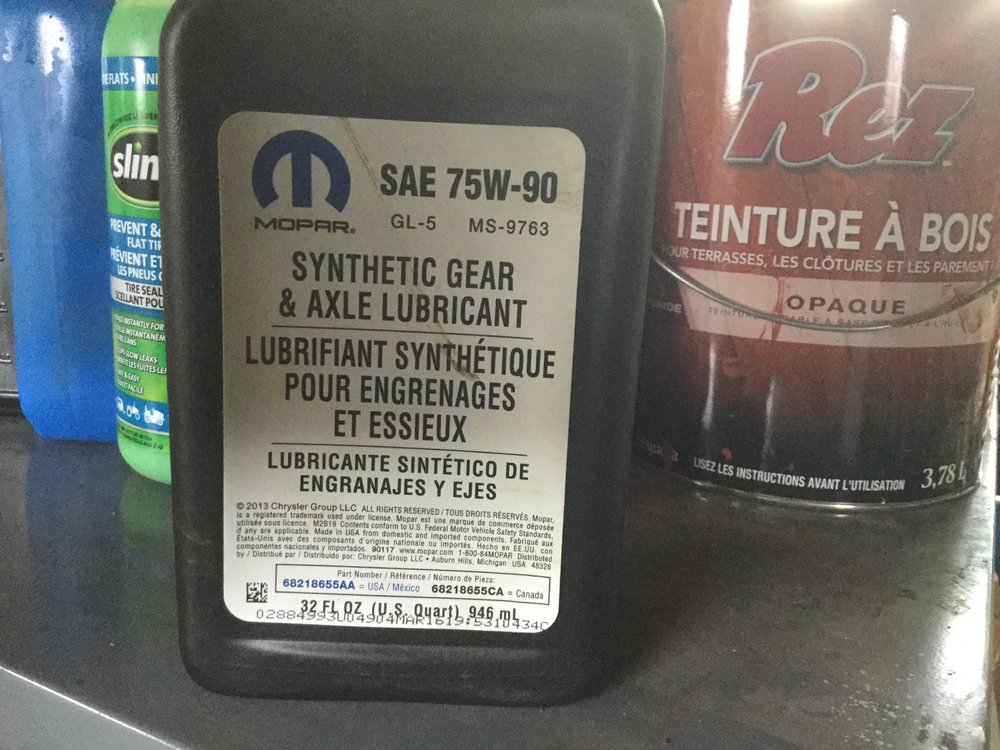

Glad you got it done. I need to do this again soon on mine. Some times a bit of a flush helps a little too. As long as there is no large particles of metal in the oil you should be fine. I used the Mopar stuff last time, close to after market price.

-

BCM body ground control module if it’s bad can create a lot of weird difficult to diagnose problems on a vehicle. Not sure if it’s tied into climate control on a journey. The module has to match exactly the options on a car for it to be effective, so recycled parts from a wrecker not a good option with this type of electronic part.

-

It’s air intake throttle body with plastic shroud leading to air filter. Little finicky with all plastic parts.

-

2013 Journey 2.4L - No Crank, No Start

John/Horace replied to FourthGauge's topic in Electrical, Battery & Charging

Usually there are signs of a major engine failure, like knocking and low oil pressure, lost power etc. In original post you talked about lost power. Tough break at a tough time. I would want to put a wrench and physically make sure crank pulley can’t be turned with reasonable effort ...with my own eyes. Unless you really trust this guy. An engine and starter simultaneously seizing statistically I guess is possible. Used cars are always a gamble. Even the best engineered vehicles without proper maintenance will fail prematurely IMO. -

Welcome to the forum...free advice is worth everything you pay for it. You don’t say which engine you have. Lots of bearings spinning on front of engine that can make noise. If the tensioner pulley or idler are still original they can start to get noisy by 100k. (mine did on 3.6 engine) Remove belt and give them a spin with the belt off. Then tensioner is often sold as an expensive assembly, but Rockauto sold just the pulley with a bearing installed for reasonable $. Could run engine for 30 seconds with belt off to confirm it’s something driven by belt and not internal engine stuff; with water pump not turning don’t run it for long. This may generate codes from alternator not functioning in system. Good luck.

-

One section of intake manifold needs to be removed that is close to back of engine compartment. You will then see vent hose. Won’t show up on engine compartment pics that I’ve seen.

-

2013 Journey 2.4L - No Crank, No Start

John/Horace replied to FourthGauge's topic in Electrical, Battery & Charging

No experience fortunately. There are other symptoms of door locks, wipers also not working properly if it is TIPM issue, or so it says on line. I assume fuse F121 was not blown. If fuel pump signal was gone I would think it would still try to start car. I have had a fuel pump driver module issue on my F150. Turned out to be $10 fusable link and 3” of wire and some solder. Got off lucky. https://www.verticalvisions.com/tipm-fuel-relay-solutions.html -

Aluminum on aluminum parts often have special gaskets that never use sealant, just clean parts with lacquer thinner. They are MLS gaskets made with several layers and a special primer on outer surface for adhesion; they go on dry. Ive used them on Yamaha snowmobile jug/piston rebuilds, work great. https://www.enginelabs.com/engine-tech/sealed-with-science-tips-for-perfect-head-gasket-sealing/

-

Timing Is fixed on any vehicle I’ve ever worked on, the fixed number of gear teeth determining that. Off one tooth is often 8degrees of timing which will make vehicle run like crap. Always rotate engine at least 360 degrees two turns clockwise after belt install to make sure all markings still good, tooth hasn’t skipped by accident on one of pulleys. Dealer mechanic I knew used to paint mark existing belt and pulleys, just easy way to avoid mistakes. I do the same thing. Tension on belt is however adjustable, although lots of vehicles have spring/hydraulic loaded tensioner. I would make sure to replace the belt tensioner because of how critical it is. Stretch tty bolts should only be on cyclinder head .

-

Level of fluid matters, I fill to the second fill line. Try cleaning/inspecting reservoir like hankster suggested. If it’s a 3.6 engine the pump change will be a challenge, looks like part of exhaust needs removing. I have used suction pump and replaced all the fluid on mine more than once. The additives wear out and there is no filter in system, just a screen usually at bottom of reservoir on most cars left with hydraulics system.

-

Mounts Usually more of a high milage older car thing, but possible. Vibration at idle can often be an engine issue; scan for codes, even if no check engine light. Knocking going over bump can be dozens of things in suspension. Check for play in ball joint, tierod, sway bar links etc.

-

If there is warranty on ptu maybe go back and see them. If you are changing oil look with a magnet for metal filings.p

- 4 replies

-

- transfer case

- transmission

-

(and 2 more)

Tagged with:

-

All gear boxes and transfer cases and differentials have a vent because of differential pressure. Oil and assembly air space heat up with use and would pressurize, forcing oil out through gaskets and seals if not vented. Usually the vent tube has a small one way check valve at top to prevent contamination; on jeeps especially they go up high as they can in case anyone plays Uboat captain. I changed the oil two years ago and have no pic. I’m due to change it again in a few weeks, will post a picture then. I’ve never seen it shown on engine bay diagram.

-

https://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=2009508 Great write up on link about torque to yield heat bolts Paint mark the belt on the pulleys, transfer marks to the new belt. Some cars have recess in block where bolt goes through pulley to prevent them from moving. Should be timing marks on cams and TDC on timing cover. Mitchel is good for specs and procedures.

-

identify these parts please

John/Horace replied to wpginterceptor's topic in Brake, Chassis & Suspension

Looks like rear forward lateral arm. https://www.rockauto.com/en/moreinfo.php?pk=7525384&cc=1447563&jsn=14&jsn=14 And rear upper control arm, adjustable is what people are recommending costs a bit more, $60 plus shipping. https://www.rockauto.com/en/moreinfo.php?pk=8439460&cc=1447563&jsn=35&jsn=35 Plus the upper $7 bushing . https://www.rockauto.com/en/moreinfo.php?pk=8438860&cc=1447563&jsn=462 -

Someone needs to build one of these.